Automatic Card Counting Machine

To view this video please enable JavaScript, and consider upgrading to a web browser that supports HTML5 video

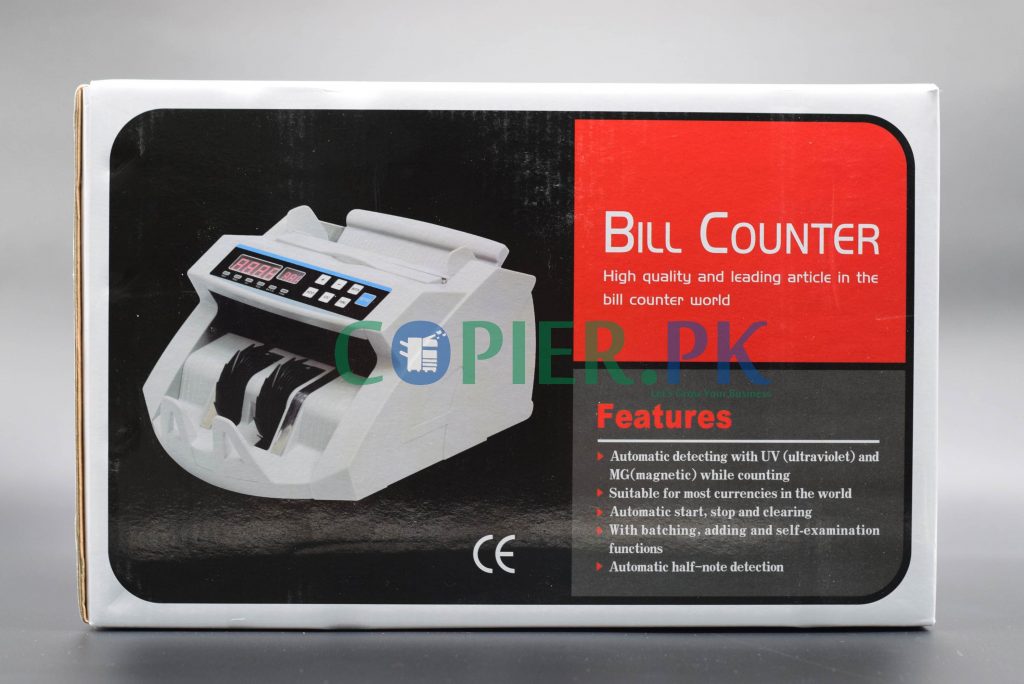

- Money Counting Machines For Sale

- Automatic Card Counting Machine

- Automatic Card Counting Machine Price

ZEAVAN Automatic Card Shuffler, Adult Elderly Electric Easy to Use Bridge Game Electric Playing Card Shuffler Automatic Poker Shuffling Machine (2-Deck) 3.9 out of 5 stars 50. Get it as soon as Tue, Mar 2. FREE Shipping on orders over $25 shipped by Amazon. Card Will Not Function 5 Years After Activation. Funds Remain Available – Call 1.800.255.0311 for Free Replacement Card. Usable up to balance only to buy goods or services online at amctheatres.com and at any box office or concession register at AMC Theatres® locations in the U.S. Card will not function five years after card activation; online redemptions and balance inquiries will be. IT'S HARD TO LEARN. First, you have to learn about the rule variations (things like 'double after. The card shuffler is great to use for anything from Poker, Texas Hold 'em, and Blackjack to trading card games. Professional card shuffler for daily board game or for competition use. Note: The product does not include playing cards. Package Included 1 x automatic card shuffler: Payment 1.

The Super 30 range of high quality twin-head sheet counting machines

If you have paper, card or money that needs counting, batch marking, tabbing or feeding you can’t count any type of paper better or more accurately than on a Vacuumatic machine and no one else can offer the same range of counting technologies:

Pin-&-blade, rotary, disc, optical, tabbing and friction feeding – all counting machines and techniques developed and manufactured in-house.

We supply state of the art paper, card and bank note counting, batch marking and tabbing machines to the security and commercial print sectors, converters and paper mills. Full consultancy and support for our counting machines is available from our UK HQ, our subsidiary in Germany and our global network of sales and service partners.

Vacuumatic pride ourselves on being a solution provider for the security and commercial printers of the world and for the converting industry.

The Thickness Compensating Feeder is an extremely versatile machine, for fast and accurate feeding counting and batching of products of fixed and mixed thickness.

We have been manufacturing machines from our head office in the UK since 1951, and distributing them worldwide through our network of distributors and our subsidiary sales and service office in Wesel Germany.

Vacuumatic can offer various solutions to suit a customer’s counting, Batching or marking requirement, including: disc, pin-&-blade, optical, friction feeders, tab inserters, and web marking devices. With our own in-house design team and the ability to outsource to specialists when required, we can be reactive to the customer’s needs. We follow a continuous development plan and are always looking for ways to improve our products and develop new ones to satisfy customer demand.

The RTIS 3 offers unparalleled waste management control by remote firing of adhesive marker labels onto the moving edge of web material.

From our fully trained service team, available to install machines, train operators and provide back up when required, and a well-stocked spares department. We can provide full after sales support and consumables/spare parts supply very quickly to keep our customers machines working at their most productive.

Our network of agents around the world have trained engineers available to look after our products, and hold stock of consumables. Vacuumatic regularly participate in the leading exhibitions and open houses held throughout the world where our machines are available for demonstrations and testing.

We are also happy to receive our customers samples for testing where we can offer advice on the correct machine to use and provide videos of your product being counted on our machinery.

You can improve efficiency in your tablets and capsules manufacturing plant by investing in high quality automatic counting machine.

It improves, accuracy, efficiency and consistency, something you probably need.

In this guide you will learn about every possible information about the automatic counting machine. It explores classification criteria, working principle, advantages and specification, among other aspects.

Let us find out how.

Automatic Counting Machine Definition

An automatic counting machine is a device that will assist you in counting the tablets or capsules that you produce.

Manual counting of tablets and capsules may be problematic and tiresome.

This maybe because you have to stand in one place all day as you count the capsules and tablets.

An automatic counting machine will do all that work for you. It has special features that operate automatically in loading and counting the pharmaceuticals.

There are two main types of counting machines which are:

- Automatic capsule counting machine for counting capsules

- Automatic tablet counting machine for counting tablets

The machine works on the principal of multi-task vibrating mechanism to count all the capsules without human effort.

You will learn more about this later in this guide.

Advantages of Automatic Counting Machine in Pharmaceutical Industry

Here are some of the advantages of using the automatic counting machine:

Automatic counting machine

· Robust Construction

An automatic counting machine has a robust structure and design that comes out of the construction method.

The robust construction provides additional weight that stabilizes the machine during the counting process.

· Easy to Maintain

You will spend a very short time and money when it comes to maintain an automatic counting machine. You will only have to clean and grease it regularly thus making it easy to maintain.

· Good Performance

You are sure of getting great performance from the automatic counting machine because of its working mechanism. You should expect no errors as it is very accurate in the counting process.

· Increased Throughput

The throughput from the machine is ever on the rise.

You can count as many tablets or capsules at a time depending on the size of the machine.

· Unprecedented Flexibility

You can use the machine in counting different types of tablets or capsules. All you need to do is, set the machine according to the type of tablet or capsule you will count.

· Improved Quality Control

With the help of the machine, you can reduce the risk of breaking the tablets or capsules.

It, therefore, enhances the quality of the final tablet or capsule under count.

· Cost Effective

The initial cost of the machine might be high but the operating cost is lower.

You may need to pay for the cost of power and a few assistants as everything else is automatic.

· Ease of Deployment

You can easily deploy the machine to any location depending on its size, flexibility and adaptability.

· Broken Detection Capabilities

As much as the machine does not break the pharmaceuticals, it can also detect any form of breakages. The automatic system will alert you of the broken pharmaceuticals as it counts.

· Remote Control

Since the machine is automatic, your input is minimal.

All you have to do is set the machine and you can control it remotely from wherever you will be in the factory.

· Safety

Operating the machine is very simple and safe.

In the operation mode, you will not be around the machine thus increasing your chances of safety.

Disadvantages of Automatic Counting Machine in Pharmaceutical Industry

Despite the advantages, the machine also has some shortcomings.

Here are the major disadvantages:

Counting process

· Many Designs can be Confusing to Operate

There are many designs of the automatic counting machine in the market.

This can confuse you especially when you are operating different types of automatic counting machines.

· Sensor Error due to Dust Accumulation

You might experience some problems especially when dust from the tablets accumulate on the sensors of the counting machine.

· Advanced Designs Require Training to Operate

You might need to undergo some form of training to enable you operate the advanced designs of the machine.

· Initial High Cost of Investment

You will have to dig deeper into your pockets when you are installing the machine. Purchasing the machine is expensive and so is the cost of installation.

Let us have a look at the main classifications of the automatic counting machine.

Classification of Automatic Counting Machine

There are many types of automatic counting machines.

Let us have a look at some the three main types.

Automatic Tablet Counting Machine

Tablet counting machine

Functions of Automatic Tablet Counting Machine

You will use this machine specifically for counting tablets.

You will find different types of automatic tablet counting machines that have different working rates. There are, however, special designs that can count and fill the tablets after counting.

You can get a machine that can count and fill 200 bottles of tablets in one minute.

Parts of Automatic Tablet Counting Machine

The machine has contact parts that you can easily remove for cleaning and maintenance purposes.

Here are some of the main parts of the machine:

- High speed infrared sensors that can scan 34,000 times in a second and accurately count all the tablets.

- Integrated dust and chip extraction system to remove the dust that might accumulate in the system.

- Feed Trays that will feed the machine with the tablets for counting.

- Hopper tray

- Conveyor belt for transporting the tablets from one place to another

- Hopper feeder for feeding the tablets to the feeder trays

- Hopper sensor for monitoring the level of tablets on the tray feeder. Apart from that is also switches the hopper feeder on and off.

- Flexifill system that controls the whole counting and filling of tablets into bottles.

- Trap boxes for counting the tablets of small proportions before filling them in the bottle.

- Touch screen control system for keying in the main counting parameters of the machine.

- Camera for capturing the images of the tablets as it counts them.

- Motor for controlling the movement of the conveyor belt of the machine.

- Switch for turning the machine on and off.

Working Principle of the Automatic Tablet Counting Machine

Step One: Power on the machine from the switch

All you need to do in this case is make sure that you program the machine accordingly.

An automatic tablet counting machine has a touch screen controlling system for programing it. You can indicate the time and speed you expect the machine to operate under among other requirements.

Step Two: Feeding the machine with the tablets.

The tablets will come from the tablet manufacturing machine and then to the tablet counting machine.

You can also use the machine with the automatic tablet filler which will automatically feed the machine after loading.

The tablets enter the counting machine through the feeding trays. Depending on your custom controls, the machine accurately and consistently guides the tablets.

The hopper system on the other hand continuously monitors the level of tablets in the trays.

Step Three: Actual counting using a sensor or a camera

As the tablets move across the system on a conveyor belt, the infrared sensors count the tablets.

Apart from the sensor, other machines have cameras that capture the images of tablets as they move on conveyor belt.

There is a certain set of machines that vibrate and align the tablets properly for counting purposes.

Step Four: Separating the fine tablets from the broken tablets

As the machine counts, it also detects if the broken tablets.

The system works in a way that the broken tablets will move to another side from the fine tablets.

Step Five: Filling the packaging materials

You can also connect the machine to a filling machine and it will automatically fill the packages.

The machine accurately fills the bottles and the packages with the right number of tablets.

After a successful tabletcounting and filling, you can shut it down and clean it.

Tablet counting and filling machine

Applications of the Automatic Tablet Counting Machines

Automatic tablet counting play an important role in the pharmaceutical industry. Some of the most common applications include:

- You can use the automatic tablet counting machine to count the number of tablets you are producing.

- Since the machine is compatible with the filling machine, you can use it to fill the tablets in the bottles.

- You can use the machine to detect the broken tablets and separate them from the fine tablets.

Let us look at the automatic capsule counting machine.

Automatic Capsule Counting Machine

Automatic capsule counting machine

Functions of Automatic Capsule Counting Machine

You can use the automatic capsule counting machine to count capsules.

Apart from that, you can also use the machine in detecting any faults in the capsules such as broken capsules.

Parts of Automatic Capsule Counting Machine

The main parts of an automatic capsule counting machine are:

- Feeder Trays for receiving the capsules from the hopper feeder

- Hopper feeder which receives the capsules from the automatic capsule filler

- Automatic capsule filler which automatically feeds capsule counting machine with the capsules.

- Conveyor belt which helps in moving the capsules from one station to the next.

- Motor which helps in rotating the conveyor belt ensuring constant movement

- Sensors for detecting capsules no matter the speed of movement.

- Cameras for photo electric sensing and counting the capsules

- Switch for powering the machine on and off

- Touch screen control panel for prior programing of the machine before it starts operating.

- Adjacent filling machine for filling the pharmaceutical packages.

- Automatic rejection system for rejecting the unfit capsules

- Computer system for displaying the progress of the counting process.

Working Principle of Automatic Capsule Counting Machine

Let us have a step by step look at how the automatic capsule counting machine works.

Step One: Preparing the Machine

This is the only step that will require your active input.

You will key in the main counting parameters that you need the machine to work on.

You may also fill the automatic filler with the capsules and ensure everything is okay.

Step Two: Feeding the Capsules to the Machine

As the operations commence, the automatic filler will feed the hopper with the capsules.

After that, the hopper will control the number of tablets moving into the feeder trays.

With the help of a hopper sensor, you can control the levels of capsules on the feeder trays at a time.

From the stainless steel feeder trays, the capsules move slowly and automatically by vibration to the conveyor belt.

Step Three: Actual Counting

You will control the speed at which the conveyor belt moves.

As it moves it carries a long with it the capsules.

With the help of a sensor, the machine will detect any capsule that passes through the sensor and take count.

Other machines use the photo electric detection concept to assist in counting the capsules.

As it counts, the sensor will also assist in detecting the unfit capsules. Working with automatic rejection system, it will detect and reject capsules with defects. The defects include, wrong weight and colors, incompatible sizes and broken capsules among others.

As the counting proceeds, you can check the electronic display on the computer system.

Step Four: Automatic Filling of the Capsule

After counting, the machine will automatically fill the capsules to the pharmaceutical packages.

The reject system will also separate the capsules with defects from the fit capsules.

The process continues until the number of capsule to count is complete.

Applications of Automatic Tablet Counting Machines

You can use it specifically for counting capsules.

It also fits perfectly as a damage detection machine that will reject the capsules with defects.

Modern automatic capsule counting machine come complete with a filling machine to automatically fill the packages.

Automatic Tablet and Capsule Counting Machine

Automatic tablets and capsules counting machine

Money Counting Machines For Sale

Functions of Automatic Tablet and Capsule Counting Machine

Automatic Card Counting Machine

You will use this machine to automatically count both the tablets and the capsules.

Even though, it counts both tablets and capsules, you cannot count both of them at the same time.

Parts of Automatic Tablet and Capsule Counting Machine

- Automatic tablet and capsule filler

- Hopper system with the hopper sensor, hopper trays and hopper feeders. The system allows you to control the number of capsules and tablets on the feeder trays.

- Feeder tray system which vibrates as it moves the capsules and the tablets

- Control system for you to program the operations of the machine.

- Computerized display for monitoring the progress and taking the counting records.

- Conveyor belts for moving the tablets and the capsules from one station to the next.

- Automatic detection and rejection system for getting rid of the capsules and tablets with defects

- Sensors and high speed cameras that assist in the actual counting process.

- Filling machine that will automatically fill the capsule and tablet packages.

Working Principle of the Automatic Tablet and Capsule Counting Machine

In this machine, you might have to put a little bit more input. You will have to know the different parameters for counting the capsules or the tablets.

First, you need to fill the automatic filler with the capsules of the tablets. You cannot count both of them at the same time.

After that, program the machine according to the pharmaceutical that you would like to count.

A thorough inspection of the machine is also important before you begin the operations.

Secondly, power on the machine and let the counting process begin.

The automatic feeder will feed the hopper system with either the capsules or the tablets. The hopper system will control the amount of capsules or tablets that it allows into the feeder trays. With the help of the hopper sensor, it can either cut the supply or proceed with the supply.

The feeder tray vibrates and slowly allows the capsules o the tablets on to the conveyor belt.

The third step involves the actual counting where sensors will detect every capsule or tablet that passes through.

The information on the number of tablets and capsules proceed to the computerized system. The system allows you to monitor the counting process with the complete results.

At the same time the automatic rejection system detects and puts away the capsules and tablets with defects.

The final stage involves the filling of the pharmaceutical packages. This is only possible if the counting machine has an automatic filling system.

Applications of the Automatic Tablet and Capsule Counting Machines

You can use the machine for the following purposes:

- Counting of tablets and capsules

- Detecting and rejecting any capsules or tablets with defects

Other Automatic Counting Machines in Pharmaceutical Industry

You can also use other automatic counting machines for counting other types of pharmaceuticals other than the tablets and capsules.

Since you will be producing the pharmaceuticals in bulk, you will need an automatic counting machine to know the number.

You can, therefore, get different machines that can count different types of pharmaceuticals such as:

- Syringes

- Ampoules

- Vials

The automatic counting machines that are capable of counting the different types of pharmaceuticals come in a variety of designs.

Ampoules

The working principle might, however, be the same.

Counting of pharmaceuticals often rely on the sensory system or the photoelectric counting system.

These machines use these principles to detect all the pharmaceuticals that pass through the system. The sensors will detect any syringe, vial or ampoule that passes through it and take count.

The photoelectric system depends on very powerful cameras that will take the images of the pharmaceuticals and take count.

Your input in the automatic counting system is very minimal. The machines allow you to program and monitor progress from a distance.

The mode of operating these machines id often quite simple. Apart from that, other machines come complete with an on screen display.

The display will guide you on the mode of operation and give you full instructions to follow.

The ease of cleaning the machines after use makes maintenance very simple. You can, therefore, use the machine for a longer period.

With that in mind, we can proceed to the factors to consider when you purchase an automatic counting machine.

Considerations when Buying Automatic Counting Machine

Whenever you decide to purchase an automatic counting machine, here are some of the factors to consider:

Automatic counting and filling machine

i. Automation software and hardware

Different machines have different automation hardware and software. Make sure you go for the latest hardware and software that you can operate comfortably.

ii. Production capacity

Make sure that you know the exact production capacity of your operations. You can, therefore, go for a machine that can comfortably count the amount of pharmaceuticals that you produce.

iii. Quality compliance

All the machines that you will be using need to comply to the quality standards. You should ensure that every machine you intend to purchase also complies to the quality standards.

iv. Brand/model

Many manufacturers produce different types of machines with varying capabilities. You should go for the model that works well with every tablet or capsule manufacturer.

v. Type of Pharmaceutical you produce

The market has both capsule and tablet counting machines. You will go for the tablet or capsule counting machine depending on the type that you produce.

vi. Budget

The budget that you are operating will influence the type of machine that you will purchase. The more money you have the better the automatic counting machine.

vii. Level of experience

Automatic Card Counting Machine Price

You should go for a machine that you can operate easily without hitches. You might need to undergo special training in case you purchase other sophisticated counting machines.

Conclusion

Still thinking about quitting?

I think you do but this time, you will be quitting for the right reasons.

What are you waiting for?

Give up the monotonous counting process and adopt the automatic counting machine.

Pick up your phone and negotiate the best deal with your supplier for a good automatic counting machine.